Enable Infrastructure Concluding on Tactile Installation at 100 Platforms Across 43 Stations in the Sussex, Kent and London Area.

Enable Infrastructure Concluding on Tactile Installation at 100 Platforms Across 43 Stations in the Sussex, Kent and London Area.

8 March 2021

Enable Infrastructure (formerly known as BCM Construction) are concluding on their successful tactile contract as part of the Year 2 Capex CP6 Framework, working directly for Network Rail.

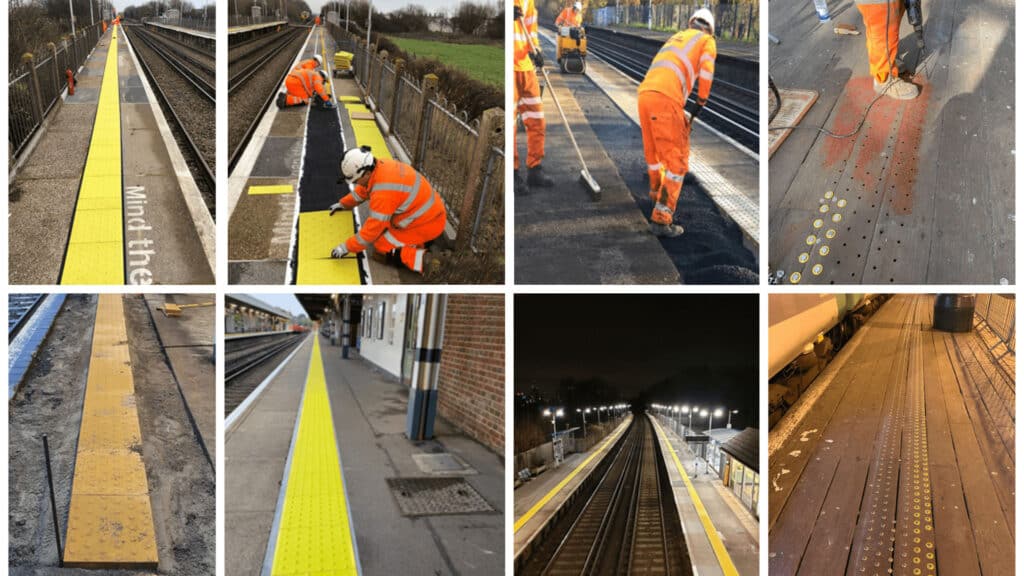

Enable Infrastructure have completed the majority of planned improvement works which consisted of 100 platforms across 43 Stations in the Sussex, Kent and London area, installing in excess of 16,500m of tactile. This was a self-delivered contract with Enable Design (formerly known as Equate Design) expertly delivering on the design and surveying whilst our resourcing company Crewit supplied experience staff to execute the works. The project commenced back in August 2020 and are set for completion at the end of March 2021.

With the wide assortment of stations, historic features, and diverse requirements, four different tactile methods were used for the renovation works. Two stick on tactile solutions were used; Viztek and Visul with Visul also supplying the specialist adhesive for use with the tactiles. Marshall’s traditional concrete tactile was also needed for several platforms as well as stainless steel studs as an alternative to the traditional/stick on tactiles. This was on a historic listed timber Platform at Brighton Station.

All of the Enable Infrastructure teams had rigorous training from both Visul and Viztek until our teams were above the desired standard and deemed equipped to fit the tiles to the industry standard. Further to this, Enable Infrastructure employed Viztek supervisors for the first couple of weeks for quality control and to ensure Enable Infrastructure were hitting the standards.

Enable Infrastructure surveyed and produced survey reports for each platform prior to the work starting. At several sites it was identified that the existing platform surfaces were unsuitable meaning the platform surface needed to be broken out, resurfaced and after a 28-day period we were then able to lay the stick on tactiles.

There are 3 teams overseeing the scope of works. 2 of the teams specialise in the installation of stick on tactile with the third team focuses on resurfacing and the installation of traditional tactiles. These teams are predominantly performing works in midweek night line blocks and weekend possessions where available.

The biggest challenge to contend with during these works was the weather conditions, especially with the stick on tactiles. This is due to the fact that they cannot be installed when conditions are too cold and wet. Further challenges are the accessibility hours when working midweek nights as the duration of time to work is minimal and curing times need to be allowed for before the first passengers arrive at the station. However, due to the initial trailing and experience of the team, we have delivered on the completed works to the highest standards.